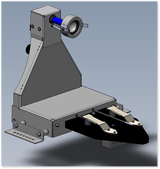

Slurry robot JOZ

Fully automatic slurry robot for dairy barns

The animal-friendly, noiseless JOZ-Tech system scrapes the manure alleys spotlessly clean, even into the smallest of corners, at a controlled speed.

The robot uses patented sensor technology. As a result, even between the cows and in extreme conditions, the JOZ-Tech is very reliable.

The system can handle large areas, without a problem. The JOZ-Tech is highly manoeuvrable and can rotate around its own axis. This means even the narrowest manure alleys and cross-paths can be thoroughly cleaned.

One major advantage of the JOZ-Tech is that the floor is completely free from obstacles such as guide beams, slurry scrapers, corner blocks or chains.

Thanks to the unique operating system, the JOZ-Tech leaves no manure residues at the end of the manure alley.

Wir haben bereits eine Vielzahl an JOZ Entmistungsrobotern installiert und in Betrieb genommen.

Werfen Sie doch einen Blick auf unsere Referenzen...

Robot in operation

Technical overview

Charging station:

The robot drives to the charging station if loading the batteries or filling water into the optional water tanks is necessary.

The charging station can be integrated into the room of one cubicle and must not be entered by animals.

Necessary infrastructure is one power supply and if watertanks are used a frost protected water pipe.

Spraying:

With the optional water spraying system the robot does not only remove manure manually but in addition can apply moisture to dry places in the barn for a better cleaning result.

Winter operation:

Installation:

Technical data:

Slurry robot in operation

Testen der Reaktion der Tiere auf den Roboter während der Fresszeit.

Selbst am Fressgitter reagieren die Tiere gelassen auf den heranfahrenden Robot und wechseln erst kurz vor diesem den Fressplatz.

Reinigen des Vorwarteplatzes des Melkstandes vor dem Melken.

Die Reinigung des Platzes sorgt für sauberere Klauen und mehr Sauberkeit im Melkstand.

Bilder des Robots im Einsatz